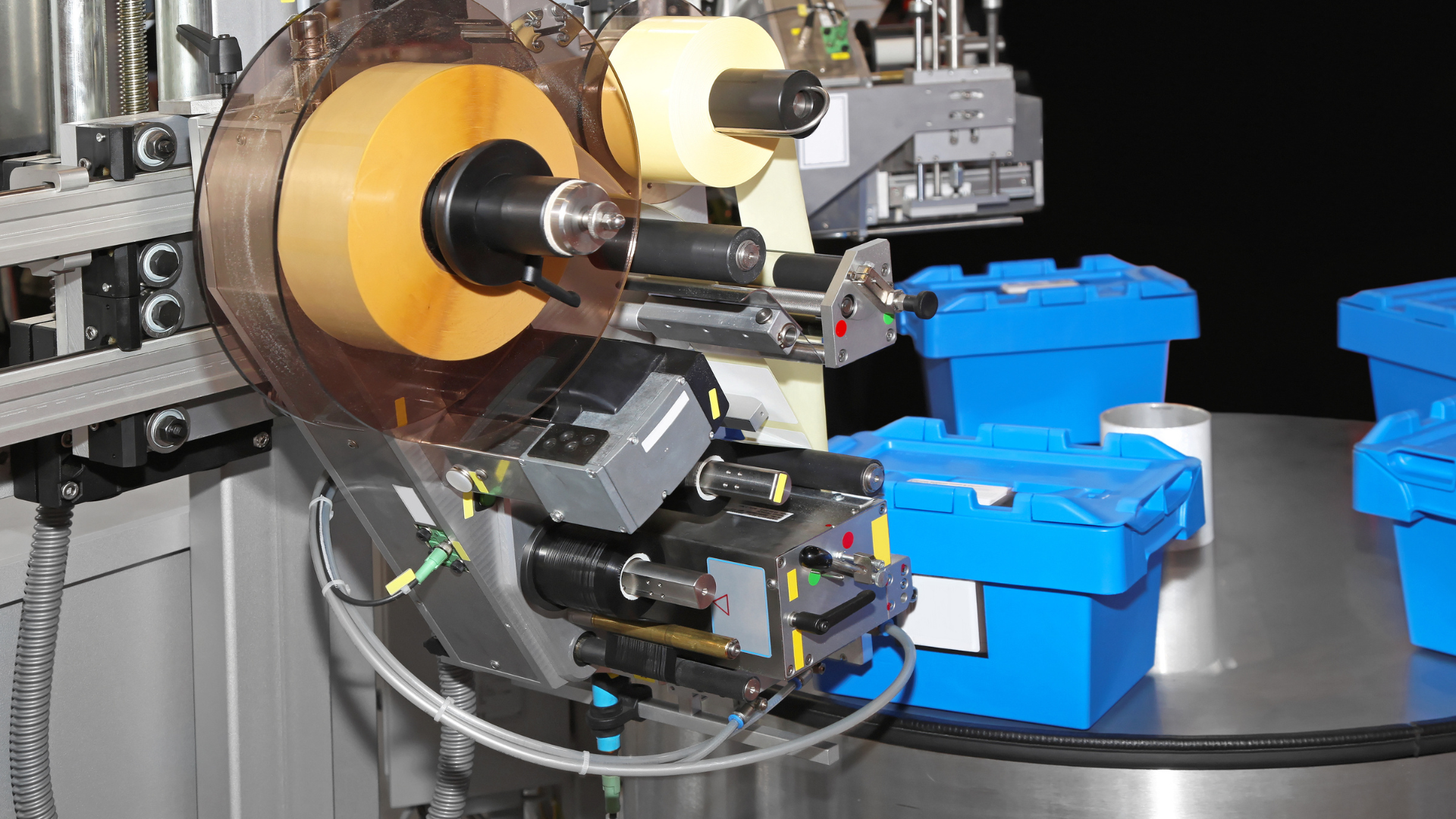

There are a lot of labeling machines on the market these days. It can be tough to know which one is right for your business. In this article, we’ll take a look at some of the mistakes you should avoid when printing labels with a labeling machine. By avoiding these mistakes, you’ll be able to get the most out of your labeling machine and improve your business’ productivity.

Before we begin, consider first how much easier it would be to have a labeling machine to print your labels. It would allow you more freedom to change your designs at short notice. This would help correct anything that you needed to without having had too many printed by another business on your behalf before you realized it. This could prove to be an extremely costly mistake. You can find out more information on labeling machines by doing some research online.

So, here are our mistakes to avoid when designing your label:

Not Understanding Your Machine’s Capabilities

Before you start using a labeling machine, it’s important to understand its capabilities. Otherwise, you could end up wasting time and money on a machine that isn’t right for your needs. For example, some machines are only designed for printing labels in one color. If you need to print labels in multiple colors, you’ll need to find equipment that offers this capability.

Compare features online and consider just what type of labels you want to print. For instance, do you need barcodes? What size of label do you require to be large enough to be seen and spacious enough to list all of the ingredients in a readable font?

Not Testing Your Labels Before You Use Them

Before you print labels in large quantities, it’s important to test them out first. Print a few labels and see how they look on your products. Make sure the labeling machine is printing the labels correctly and that the labels are sticking to your products. It’s better to catch any problems with your labels before you print a large batch of them.

This is one of the advantages of having a label machine. You can trial labels before printing too many. If you were to order too many at one time from a supplier and they were to contain an error, this could prove costly. It is tempting to order in large quantities because that makes it cheaper but this can be risky if you have something wrong.

Not Maintaining Your Labeling Machine

Like any other piece of equipment, labeling machines need to be properly maintained. Otherwise, they could break down and cause costly repairs. Be sure to read the manual that came with your labeling machine and follow the maintenance instructions. This will help keep your machine in good working condition.

Not Updating Your Labeling Machine’s Software

As technology evolves, so do labeling machines. Newer models of labeling machines often have updated software that can offer more features and capabilities. If your labeling machine is starting to feel outdated, it might be time to upgrade to a newer model.

There might be a particular feature that you had not even thought about that would make life easier. Think about having different colored labels to help with identification.

Not Cleaning Your Labeling Machine

Labeling machines can get dirty over time, and this dirt can eventually result in labels that are poorly printed or that don’t stick to products. To keep your labeling machine clean, be sure to wipe it down with a soft cloth regularly. You should also clean the machine’s print head according to the manufacturer’s instructions.

By avoiding these mistakes, you can get the most out of your labeling machine and keep your business running smoothly.